DR Fuel Cell R&D Division

Since 2021, DR Fuel Cell has been participating in seven major R&D projects led by government ministries such as the Ministry of Trade, Industry and Energy (MOTIE), the Ministry of SMEs and Startups (MSS), and the Ministry of Environment (MOE), developing next-generation hydrogen production technologies. We consistently invest over KRW 1 billion annually in R&D, aiming to execute a total of KRW 7 billion in government projects and attract KRW 8 billion in private investment by 2028.

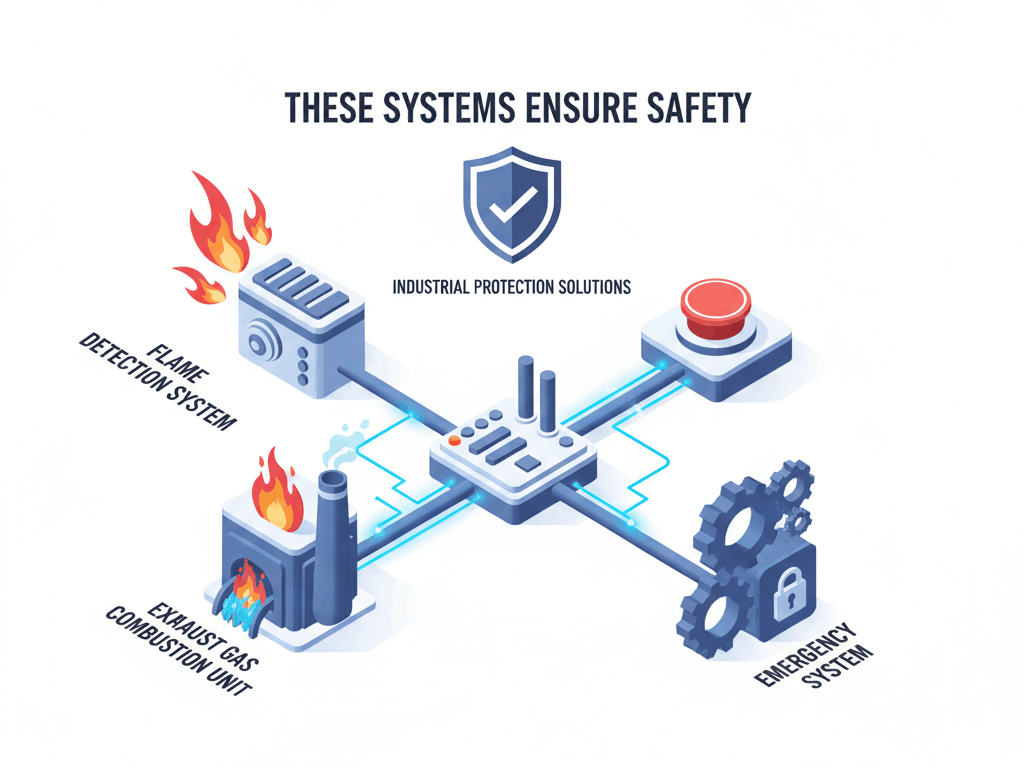

In the Safety Verification sector, we verified the safety of fuel cells integrated with hydrogen extractors for public buildings under a KETEP project. We completed the development of flame detection systems, flue gas combustion devices, and precise risk assessments, securing proven technologies commercialized for domestic fuel cell system manufacturers.

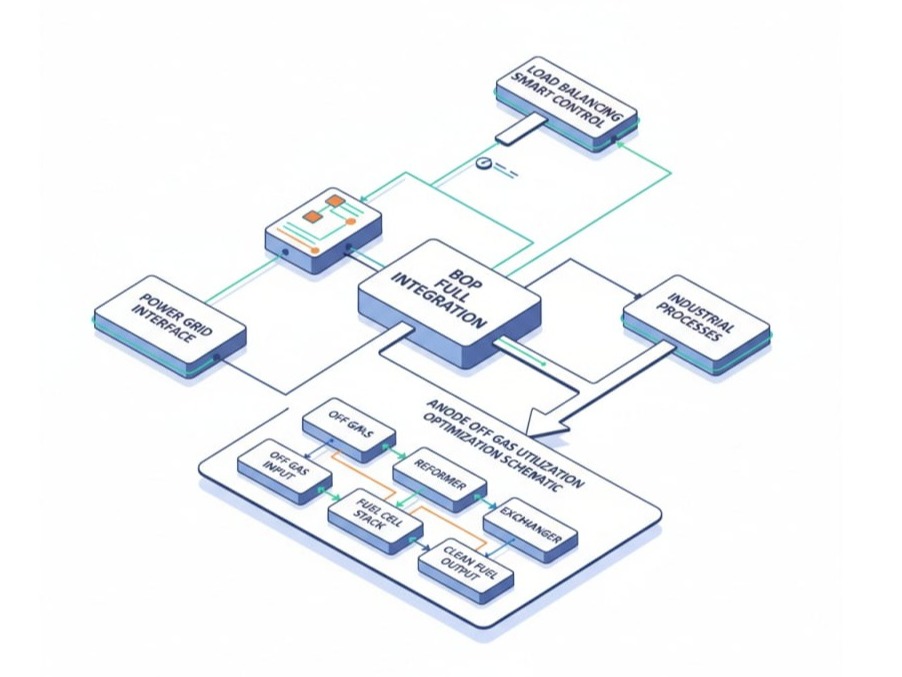

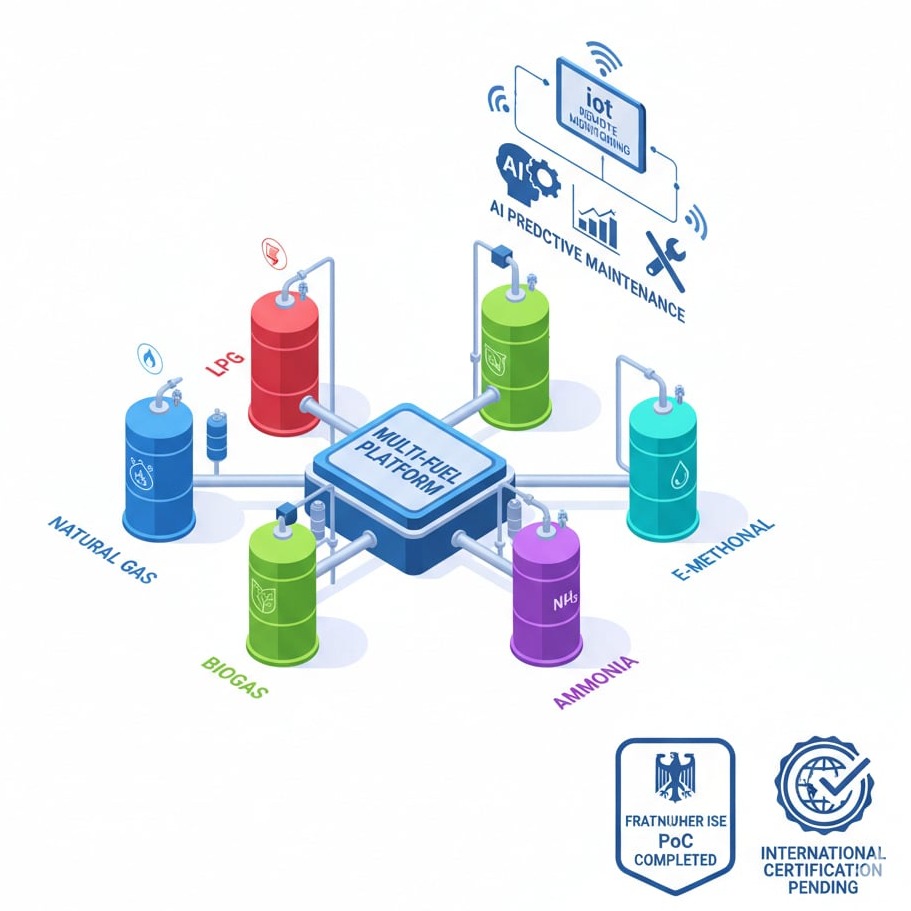

In the Smart Module Development sector, we developed hydrogen generator modules optimized for building fuel cells through the MSS Purchase-Conditional New Product Development Program. We realized an intelligent control system with load adjustment and a fully integrated BOP design. Prototypes ranging from 1kW to 50kW have been produced and are currently undergoing verification with major fuel cell manufacturers.

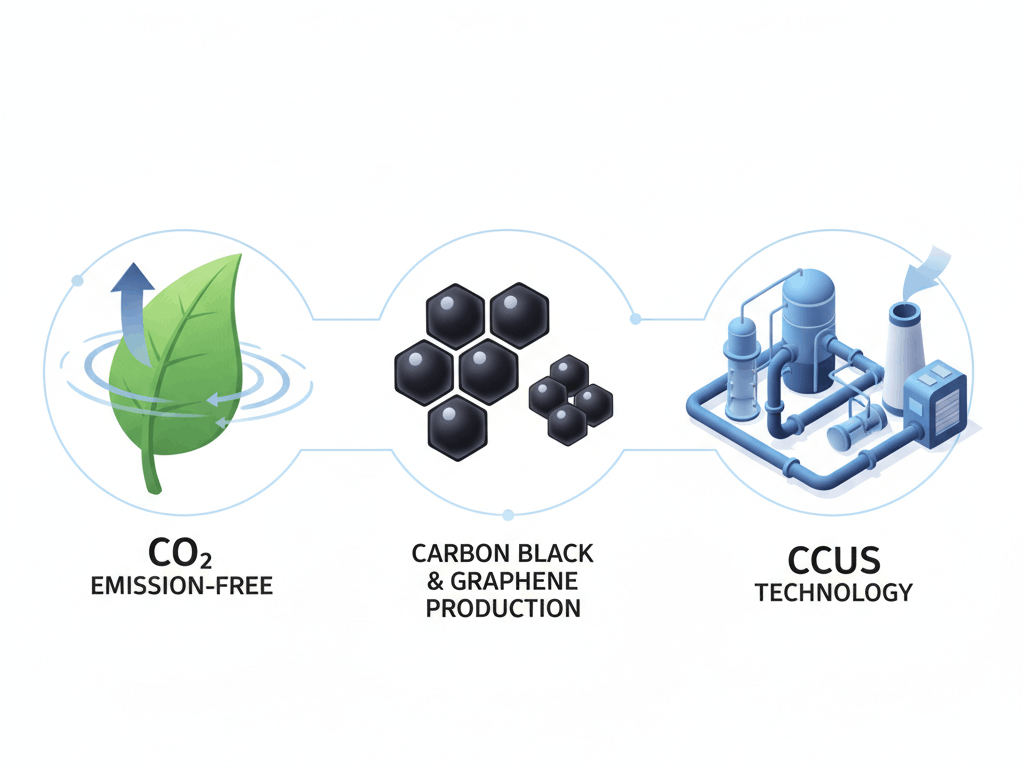

In the Clean Hydrogen Technology sector, we are researching turquoise hydrogen production and continuous carbon material manufacturing through a KEIT project. This innovative technology simultaneously produces hydrogen and high-value carbon materials (carbon black, graphene, etc.) via methane pyrolysis without CO₂ emissions. We aim to build a pilot plant by 2027 and present a new paradigm for carbon-neutral hydrogen production.

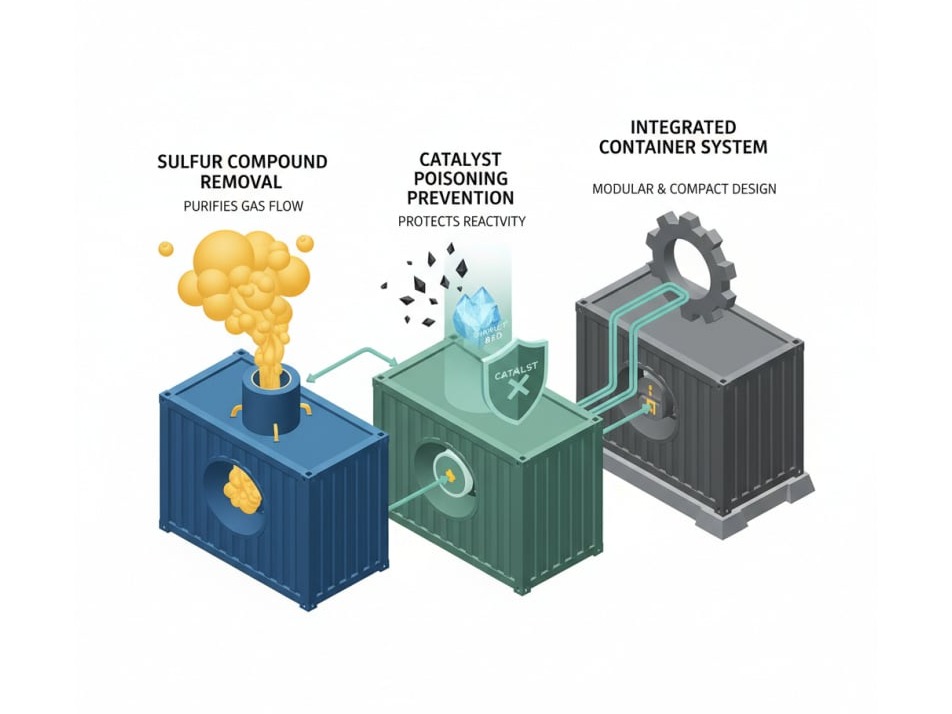

In the Biogas Utilization sector, supported by the MOE Eco-Startup Program, we developed direct biogas reforming technology, securing capabilities for sulfur and silicon compound removal and catalyst poisoning prevention. We are preparing for verification at actual biogas plants and aim to contribute to the circular economy by applying this to sewage and food waste treatment facilities nationwide.

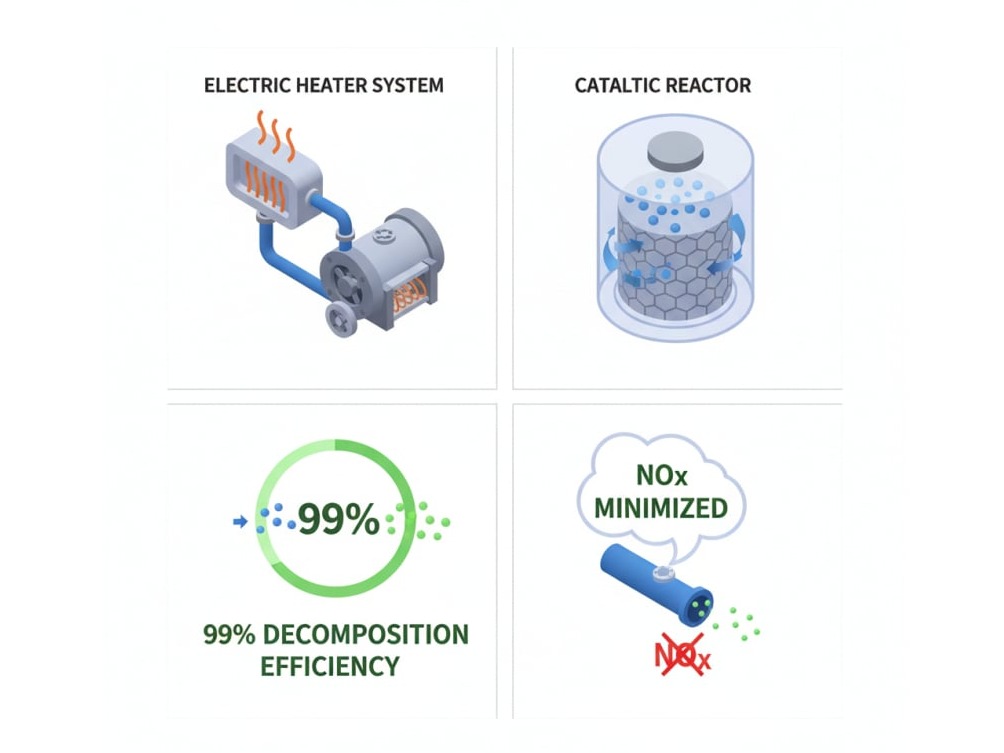

In the Ammonia Cracker sector, through the MSS Global Cooperation R&D Project, we developed an ammonia fuel cell system for marine and power generation use, completing a 1kW prototype. We laid the foundation for entering the European market through joint research with Fraunhofer ISE in Germany. We are targeting the development of a commercial system by 2026 in cooperation with marine fuel cell companies such as Doosan DMI.