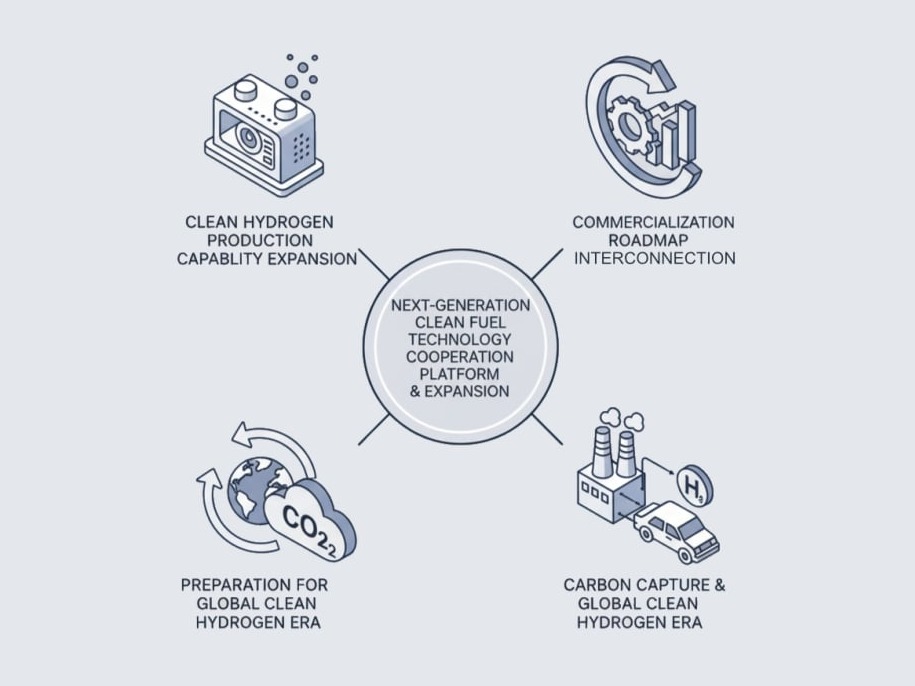

Rationale and Background of the Core Mission: Global Partnership

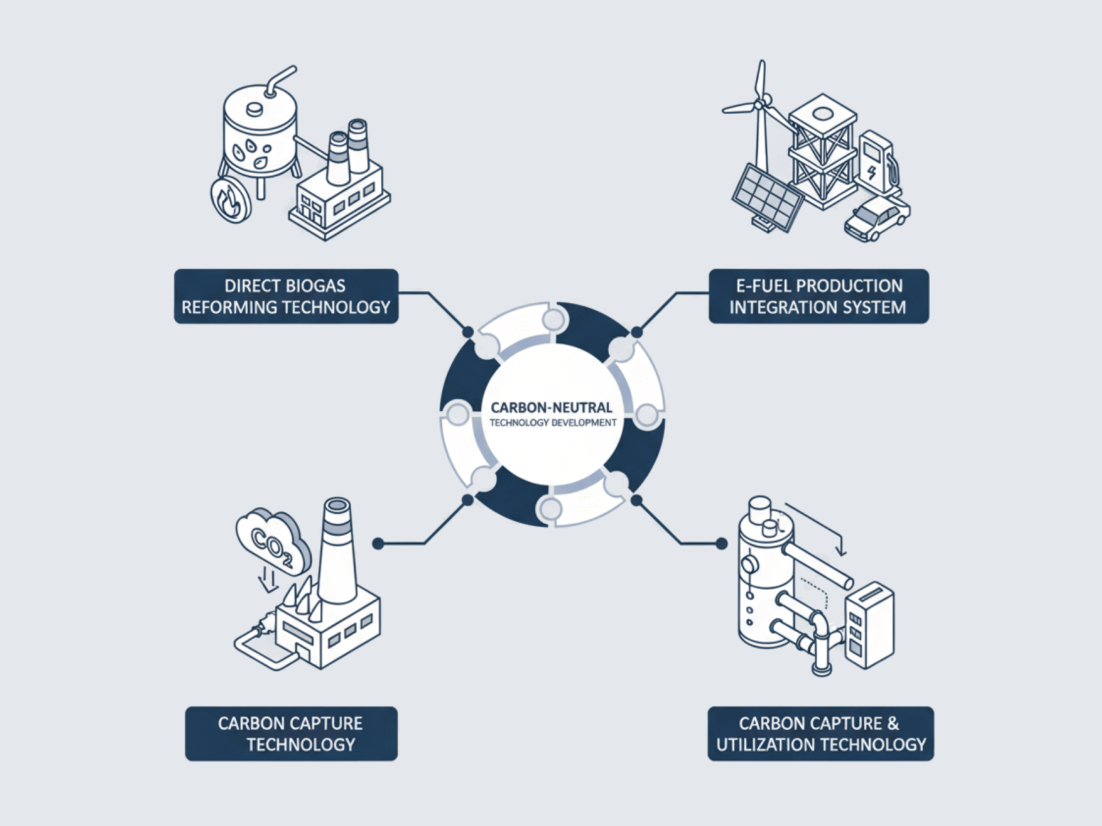

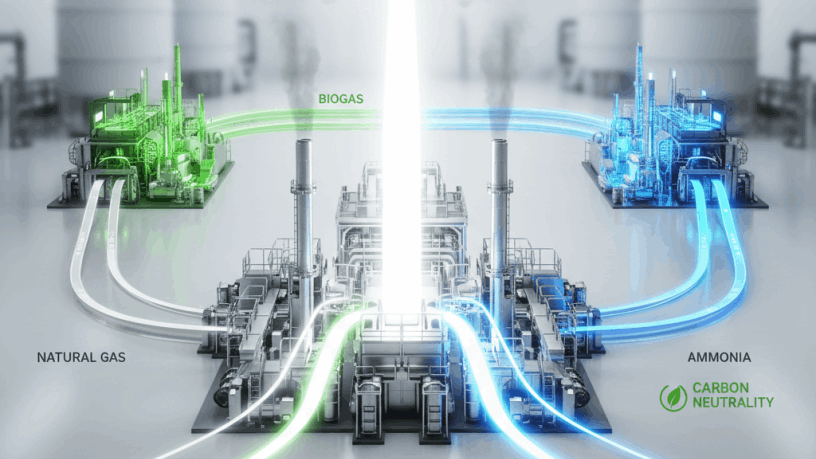

"Fuel Flexibility," achieved through the development of multi-fuel (Natural Gas, LPG, Biogas, Ammonia, e-Methanol, etc.) compatible hydrogen generation solutions, has been a consistent strategic direction for DR Fuel Cell since its establishment in 2018. By aiming to serve as a "Bridge Technology" during the energy transition, we are strengthening our position as a provider of practical hydrogen infrastructure solutions that connect the present with the future.

Necessity of Fuel Diversity

While natural gas-based hydrogen production dominates the early stages of the hydrogen economy, the transition to clean hydrogen sources such as biogas and ammonia is essential to achieve carbon neutrality goals.

Regional Differences in Fuel Availability

Available fuel sources vary by country and region. For instance, Europe has well-developed biogas plants, whereas Japan and South Korea are focusing on building infrastructure for ammonia imports.

Diversification of Customer Requirements

Fuel cell system manufacturers require hydrogen generators compatible with various fuels. This enables flexible responses to market changes and facilitates entry into global markets.